50-30000L Combo Plough Mixer for Various Daily Care Aromas Powder

Overview Product Description 1. Introduction:Ploughshare mixer with oil spray system is used to mix dry powder, granules

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | PM |

| Certification | CE, ISO, CCC |

| Application Area | Food |

| Layout Type | Horizontal |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Milling, Drying, Liquid/Oil Spraying |

| Operating type | Cycle Operating |

| Condition | New |

| Steel Material | Stainless Steel 304,316L,Carbon Steel, Ti Alloy, |

| OEM/ODM | Yes |

| Sample Test | Yes |

| Customized | Yes |

| Motor | ABB,Siemens,Mitsubishi,China Top Brand |

| Reducer | Flender,Sew,Nord,China Top Brand |

| Bearing | SKF,NSK,FAG,China Top Brand |

| Shaft Seals | Air Seal,Mechanic Seal,PTFE Seal,Rubber Seoil Seal |

| Applied Industry | Food, Chemical, Pharmaceutical,Energy,New Material |

| Delivery Time | 40 Days |

| Power Supply | 110~660V,50/60Hz,Single/3-Phase |

| Liquid/Oil Spraying Function | Optional |

| Heating/Cooling Jacket | Optional |

| Vacuum System | Optional |

| Drying System | Optional |

| Transport Package | Standard Export Packing |

| Specification | 50~30000L |

| Trademark | Higao Tech |

| Origin | China |

| HS Code | 847982 |

| Production Capacity | 500 Sets/Year |

Product Description

1. Introduction:Ploughshare mixer with oil spray system is used to mix dry powder, granules, low fibrous materials and mix paste with low viscosity, and spray liquid together.

2. Principle and features:

Ploughshares are set on the blending shaft. When plough shear mixer works, the ploughshares will make lengthwise movement at radial direction simultaneously. Its special structure leads the materials to be continuously mixed.

Meanwhile materials is scattered by the high speed shear cutters continuously installed on the side of the mixing barrel, finally materials will do three-dimensional movement under several types of force, which avoids dead corner and ensures high accurate mixing effect.Detailed Photos

| PM Series Ploughshare Mixer of HIGAO TECH | |||||||||

| Model | Total volume | Loading volume | Capacity | Loading coefficient | Mixing time | Motor/speed | Chopper/speed | Dimension(L×W×H) | Weight |

| PM-100 | 100L | 50L | 50kg | 40~60% | 0~999Min | 3kw/120rpm | 1.1kw/1440rpm | 1200×760×790mm | 400kg |

| PM-200 | 200L | 100L | 100kg | 40~60% | 0~999Min | 4kw/90rpm | 1.1kw/1440rpm | 2100×650×980mm | 550kg |

| PM-300 | 300L | 180L | 200kg | 40~60% | 0~999Min | 5.5kw/81rpm | 1.5kw/1440rpm | 2300×700×880mm | 750kg |

| PM-500 | 500L | 300L | 300kg | 40~60% | 0~999Min | 7.5kw/80rpm | 1.5kw/1440rpm | 2700×800×1240mm | 800kg |

| PM-1M3 | 1M3 | 0.6M3 | 600kg | 40~60% | 0~999Min | 11kw/67rpm | 1.5kw/1440rpm | 3200×1100×1400mm | 1200kg |

| PM-2M3 | 2M3 | 1.2M3 | 1200kg | 40~60% | 0~999Min | 15kw/65rpm | 1.5kw/1440rpm | 3900×1250×1650mm | 2500kg |

| PM-3M3 | 3M3 | 1.8M3 | 1800kg | 40~60% | 0~999Min | 22kw/42rpm | 3kw/1440rpm | 4500×1350×1700mm | 3000kg |

| PM-4M3 | 4M3 | 2.4M3 | 2500kg | 40~60% | 0~999Min | 22kw/42rpm | 3kw/1440rpm | 5000×1450×2000mm | 4500kg |

| PM-5M3 | 5M3 | 3M3 | 3000kg | 40~60% | 0~999Min | 30kw/37rpm | 4kw/1440rpm | 5300×1600×2100mm | 5500kg |

| PM-6M3 | 6M3 | 3.6M3 | 3600kg | 40~60% | 0~999Min | 37kw/37rpm | 4kw/1440rpm | 5600×1620×2200mm | 6500kg |

| PM-8M3 | 8M3 | 4.8M3 | 4800kg | 40~60% | 0~999Min | 45kw/31rpm | 4kw/1440rpm | 5100×1750×2500mm | 8000kg |

| PM-10M3 | 10M3 | 6M3 | 6000kg | 40~60% | 0~999Min | 55kw/31rpm | 5.5kw/1440rpm | 5650×1800×2650mm | 9000kg |

| PM-12M3 | 12M3 | 7.2M3 | 7200kg | 40~60% | 0~999Min | 55kw/27rpm | 5.5kw/1440rpm | 5680×1800×2650mm | 11500kg |

| PM-15M3 | 15M3 | 9M3 | 9000kg | 40~60% | 0~999Min | 75kw/27rpm | 5.5kw/1440rpm | 5850×2000×2900mm | 13000kg |

| PM-20M3 | 20M3 | 12M3 | 12000kg | 40~60% | 0~999Min | 90kw/23rpm | 7.5kw/1440rpm | 6100×2400×3160mm | 16000kg |

| PM-30M3 | 30M3 | 18M3 | 15000kg | 40~60% | 0~999Min | 110kw/23rpm | 7.5kw/1440rpm | 6250×2550×3350mm | 21000kg |

Why choose us?

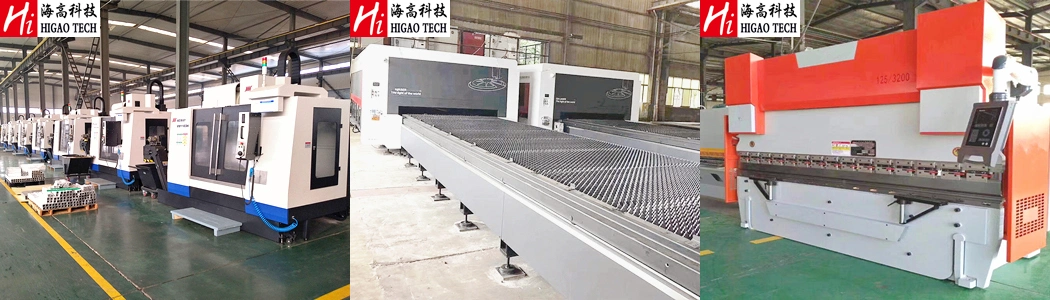

1. Real Steel Material: we have spectrometer for customer to check the material.

2. High machining accuracy: we use top brand CNC machining center, plasma and laser cuting machines, etc. to process components.

3. Professional work team: 10 engineers more than 20 year experience in R&D. Some production staff more than 30 year experience.

4. Standard production rules: we follow 5S industrial management standard to carry out our orders.

5. Strict quality control: we have QC to follow and check each working procedure as per industrial standard.

6. Customer approval: we have served more than 1000 customers in more than 50 countries.

7. Competitive price: German quality with Chinese price.

FAQ

1. How can I know your quality?

Our company is famuous in our industry. We have more than 20 years history. The best way to know the quality is comparison. You can come to our factory for on-the-spot investigation. You are welcome.

2. Can you supply sample test?

Of course our company can supply sample test before buying. And record the testing result and send to you by pictures or video.

3. What is your delivery time if I place order?

Usually 30~60 days. It depends on the machine itself, our actual order status.

4. Can you supply installation and commissioning service abroad when we received our equipment?

Yes, our company can send our engineers to your local workshop to guide installation and commissioning and training your operators.

5. How to operate and maintain the machine?

We will give you operation manual, drawing, circuit diagram spare parts list, etc after shipping.

6. What should I do if we can not solve the problems some times?

You just need to send email or make a call to us. We will reply within 12 hours and analyse the problems with you. Find the reason and find the way.

If we can not solve by communication after trying several ways, we can send our engineer to your place if you need.

7. What is your warranty period?

We supply one year warranty and life time after sales service for our euqipment.